Creating the perfect packaging design can be daunting when there are countless opportunities and techniques to use for graphics. One unique technique you can use for your product packaging includes embossing or debossing graphics.

This brief overview discusses embossing vs. debossing and everything you need to know about these design methods. Read about what each method entails, its differences, how the process works, which to choose, and more.

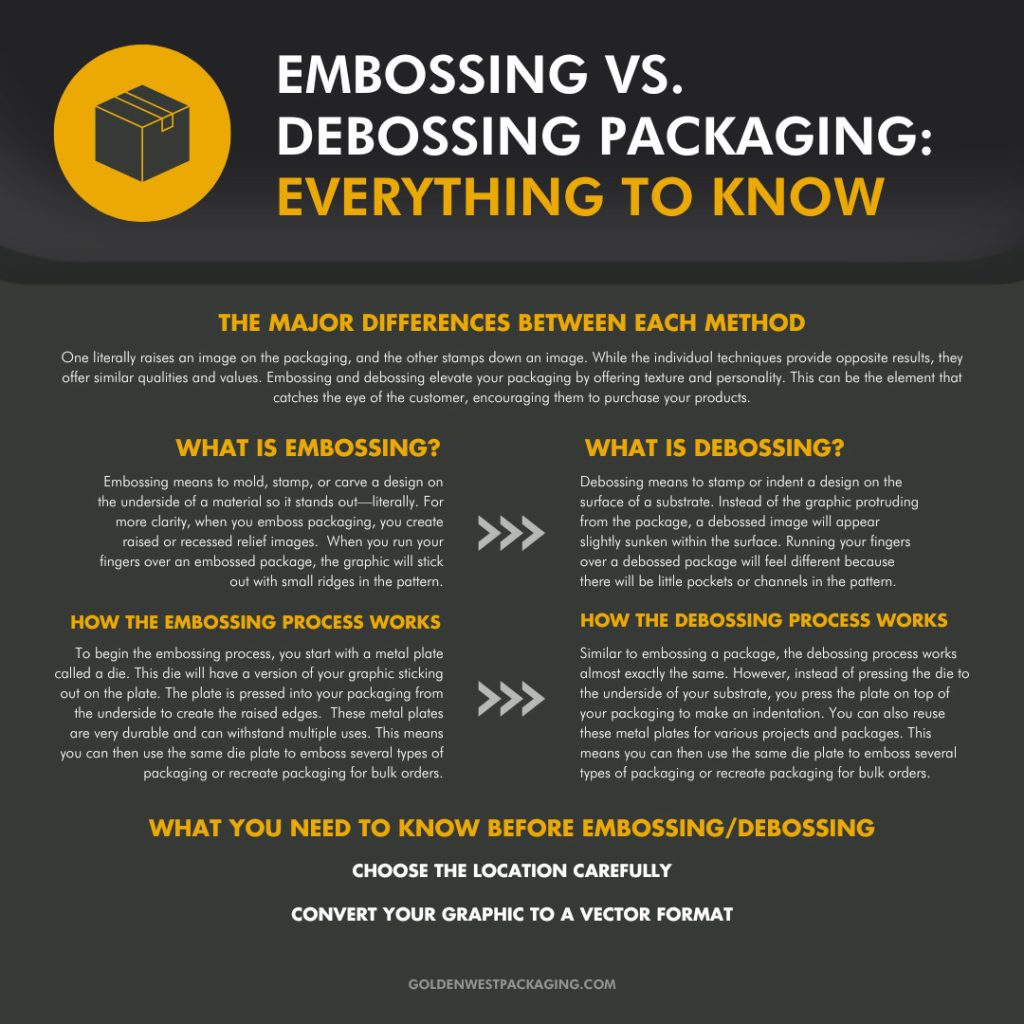

What Is Embossing?

Embossing means to mold, stamp, or carve a design on the underside of a material so it stands out—literally. For more clarity, when you emboss packaging, you create raised or recessed relief images. When you run your fingers over an embossed package, the graphic will stick out with small ridges in the pattern.

What Is Debossing?

Debossing means to stamp or indent a design on the surface of a substrate. Instead of the graphic protruding from the package, a debossed image will appear slightly sunken within the surface. Running your fingers over a debossed package will feel different because there will be little pockets or channels in the pattern.

The Major Differences Between Each Method

The major difference between each method of embossing and debossing is the appearance of the graphic. Now that you understand what each method entails, it’s easy to see their contrasting qualities. One literally raises an image on the packaging, and the other stamps down an image.

While the individual techniques provide opposite results, they offer similar qualities and values. Embossing and debossing elevate your packaging by offering texture and personality. This can be the element that catches the eye of the customer, encouraging them to purchase your products.

How the Embossing Process Works

To begin the embossing process, you start with a metal plate called a die. This die will have a version of your graphic sticking out on the plate. The plate is pressed into your packaging from the underside to create the raised edges.

These metal plates are very durable and can withstand multiple uses. This means you can then use the same die plate to emboss several types of packaging or recreate packaging for bulk orders. These dies can also be made in numerous sizes to accommodate all types of projects.

How the Debossing Process Works

Similar to embossing a package, the debossing process works almost exactly the same. However, instead of pressing the die to the underside of your substrate, you press the plate on top of your packaging to make an indentation.

You can also reuse these metal plates for various projects and packages. Depending on your desires and preferences, you could even use the same die plate to emboss and deboss.

What You Need To Know Before Embossing/Debossing

Before you begin embossing or debossing your packaging, there are other things you need to know first. You can’t jump right into creating a die plate and stamping it into a substrate. Here is what you need to keep in mind.

Choose the Location Carefully

It’s challenging to construct a design when you don’t know what space on your package it will occupy. Diving right into creating a die plate could cause issues because you might end up making a graphic that is too big or too small for the location you want to stamp it.

Look closely at your custom rigid boxes to determine the precise location you want this graphic to go. With the correct dimensions, you have a better idea of sizing and the available space for extra details. Ensure this is one of the first steps you take in the design process to avoid major hiccups or mistakes down the road.

Convert Your Graphic to a Vector Format

A vector graphic is when you create visual images using computer graphics from geometric shapes, such as lines or curves. The reason you want to convert your images into a vector format is to keep the quality of the design. When using vectors, you can resize a graphic as big or small as you would like without compromising the quality of the image.

Pro-tip: Do not go overboard with your design. Too many details can muddle the graphic or distort the image. As a rule of thumb, the simpler you can make the design, the better the results!

How Embossing/Debossing Adds Value to Packaging

The embossing/debossing techniques add significant value to your packaging; standing out from the competition, inviting customers to touch your products, and generating a higher-quality package are three such benefits. Let’s take a look at the value you can gain from these graphic design techniques.

Stand Out From the Competition

First, a package with embossing or allows your business to stand out in contrast to plain or boring packaging offered by the competition. Not only are these graphics enjoyable to look at, but they’re also fun to touch and feel. Design is all about the details, and careful attention to attractive and interesting design elevates your packaging.

Provide Unique Visuals for Customers

Dimensional design work also gives the customer a unique sensory experience. Not all businesses use these techniques when designing their packaging. Doing so conveys your uniqueness and tells shoppers that your products offer something the competitors do not.

Generate Higher-Quality Packaging

Traditional packaging solutions might include a folding carton with a single graphic design. While there is nothing wrong with minimalist packaging, embossing and debossing can generate a higher-quality package. When your packaging looks and feels luxurious, you can expect the same from the products inside.

Which Technique Should You Use for Your Packaging?

When you’re deciding which technique to use for your packaging, it will come down to preferences. There is no right or wrong way when choosing embossing or debossing.

Either technique you choose can offer value and quality to your packaging. If you’re having a hard time with your decision, consider looking at other businesses that used each method to determine which one will look best for your products.

Golden West Packaging proudly serves our customers with the ultimate design and packaging support. We offer both embossing and debossing techniques that will take your product packaging to the next level. Contact us today to speak with one of our experts to go over what we can do for your business.