Thermoformed Plastic Packaging

Recycled Plastic Thermoforming

Utilizing a variety of recycled or recyclable materials, we create thermoformed packaging trays and clamshells that offer unique industry specific solutions for the Medical, Consumer Products, and Food industry. Our class 10,000 clean room facilities meet or exceed standards for creating beautifully formed parts for clients that need their packaging to be surgically clean or food grade rated. Our heavy gauge forming equipment can also product incredibly durable parts for closed loop material handling applications.

Get custom plastic thermoforming the way you like

Securely ship your electronic components

Electro Static Dissipative (ESD) material options allow you to securely and safely ship electronic components. Whether you are shipping parts one way or in a closed loop model, ESD clamshells and trays are a great solution for computer memory, circuit boards, or other static sensitive parts.Both blended and topical coating options are available. You can also scan barcodes directly though this crystal clear packaging option.

Food Safe Trays

Our REPT, PET, and Styrene trays are food safe and come in a wide variety of colors to match your product or brand. Foil options add some shimmer and all of these can be paired with our high graphics folding cartons or rigid boxes. Our food grade trays are also recyclable and can be formed into almost any shape imaginable.

Spinning and jumping

One of the most common uses for thermoformed trays is to keep product from spinning or migrating out of its intended location. Keep your logos centered and your product indexed exactly like you want using the snap in features we can design into your tray or clamshell.

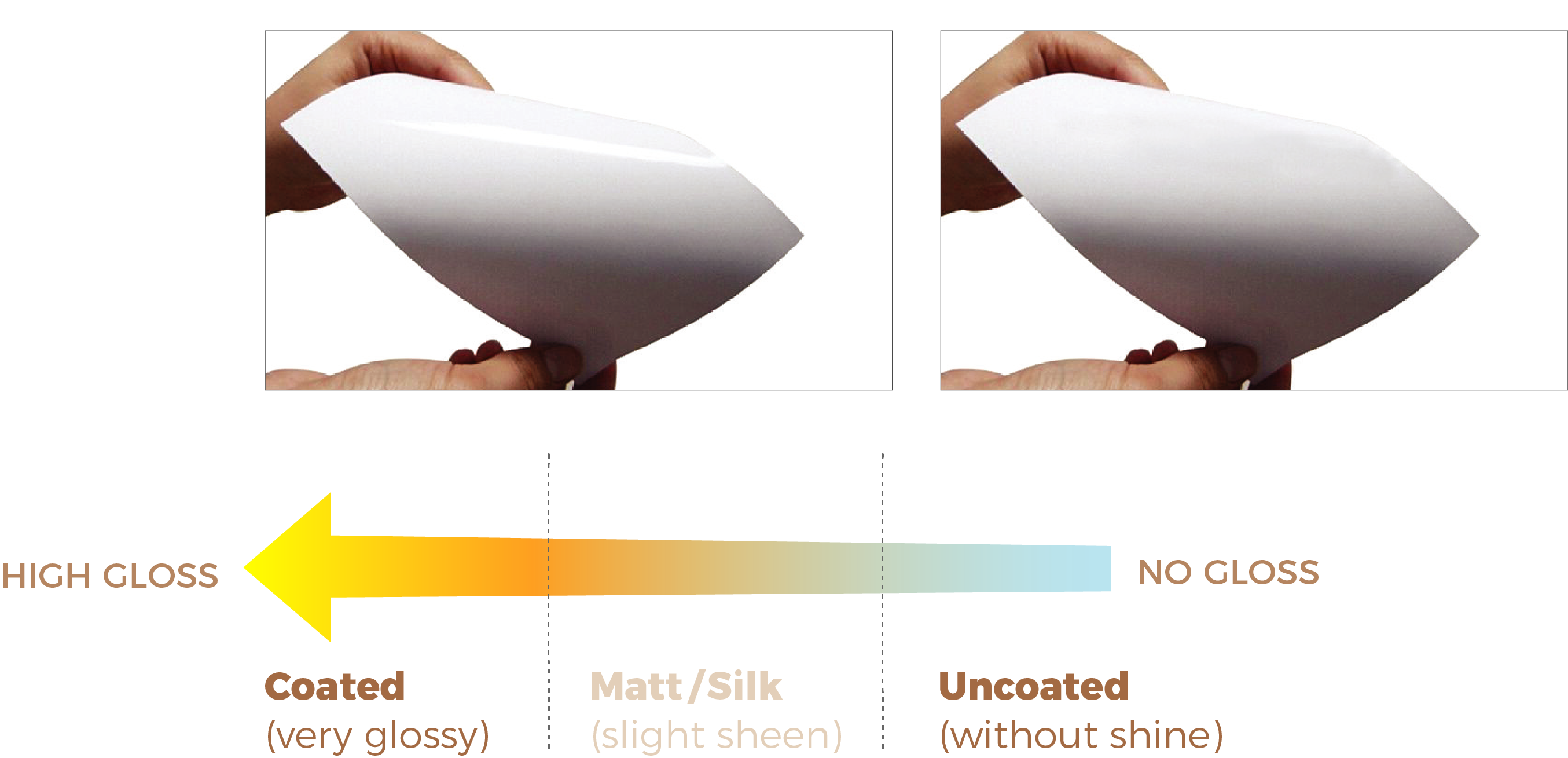

Plastic Thermoforming Packaging Material & Options

Our wide selection of popular styles

Start your packaging journey with Golden West Packaging

Get in touch with our product specialist now

Get Started