Custom-Molded Pulp Packaging

What is Molded Pulp?

Bagasse also known as sugarcane pulp, is a fibrous material left behind in the sugarcane harvesting process. Custom-molded pulp packaging is a sustainable packaging material that provides a great alternative to plastic trays. They can be formed using a variety of materials like recycled corrugated and sugar cane. They can be an all-natural Kraft color with a texture or color matched to your brands colors palette with an ultra-smooth surface. Our talented design engineers can create a beautiful and sustainable custom-molded pulp insert in a wide range of design styles and all of them can be recyclable or biodegradable depending on the material chosen.

High Performance Green Packaging

Molded pulp trays have quickly become a popular alternative to plastic trays and origami shaped paper inserts. Molded into custom shapes, and produced in a variety of colors and sustainable materials, pulp trays are a great choice for those looking for an engineered yet recyclable option to plastic or intricately folded paper inserts.

Hidden Figures

Molded pulp packaging trays are often working behind the scenes to index and protect a wide range of products. Because these trays are paper-based, they allow the insert and carton to be recycled together in the same recycling stream. Paper overlays can be produced to match the graphics on the cartons creating a seamless look.

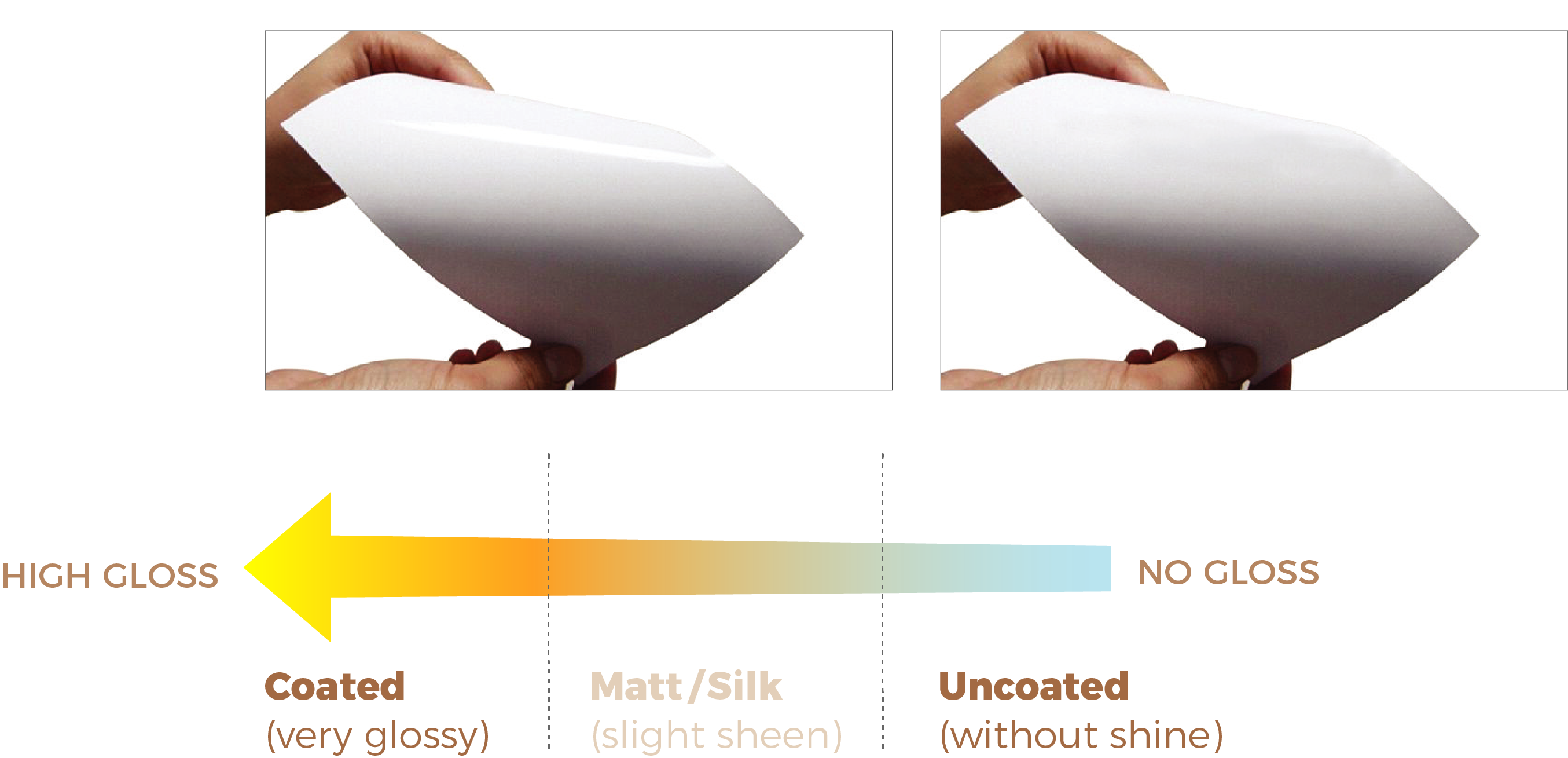

Dry and Wet Press

Molded pulp can be formed using a dry press method which is used for heavier parts that require thicker sidewalls or wet press if you’re looking for an ultra-smooth and refined finish. Color matching is available in addition to traditional natural, white, and black dyed parts.

Sizes, Shapes, and Branding

Pulp packaging material can be formed into trays, clamshells, bases and lids combos, and many other shapes. Silk screen options allow for branding opportunities directly onto the pulp parts. We can also design and manufacture full color matched paper sleeves or cartons to complete the look of this popular green packaging technology.

Molded Pulp Packaging Material & Options

Our wide selection of popular styles

Start your packaging journey with Golden West Packaging

Get in touch with our product specialist now

Get Started