-

Medical cannot be empty.

-

Food cannot be empty.

-

Consumerproducts cannot be empty.

-

Agriculture cannot be empty.

-

Contractpackaging cannot be empty.

-

Cosmetics cannot be empty.

-

Exportshipping cannot be empty.

-

Health&beauty cannot be empty.

-

Flexography cannot be empty.

-

Litholabel cannot be empty.

-

Singlefacelitho cannot be empty.

-

Digital cannot be empty.

-

Aisledisplays cannot be empty.

-

Countertopdisplays cannot be empty.

-

Clubstoredisplays cannot be empty.

-

Personalcare cannot be empty.

-

Allpaper cannot be empty.

-

Foodgrade cannot be empty.

-

Metal cannot be empty.

-

Paper+metal cannot be empty.

-

Ethylene-vinylacetate(eva) cannot be empty.

-

Polyethylene cannot be empty.

-

Polyurethane cannot be empty.

-

Styrene cannot be empty.

-

Petgtrays cannot be empty.

-

Cartons cannot be empty.

-

Roundtins cannot be empty.

-

Squaretins cannot be empty.

-

Customshapes cannot be empty.

-

Windows cannot be empty.

-

Trays cannot be empty.

-

Reusable cannot be empty.

-

Clamshells cannot be empty.

-

Trayassembly cannot be empty.

-

Winecarriers cannot be empty.

-

Makeuppalettes cannot be empty.

-

Prkits cannot be empty.

-

Protection cannot be empty.

-

Equipment cannot be empty.

-

Consumables cannot be empty.

-

Hinged cannot be empty.

-

Specialtypackaging cannot be empty.

-

Sbs/corrugated cannot be empty.

-

Displays cannot be empty.

-

Foldingcarton cannot be empty.

-

Corrugated cannot be empty.

-

Rigidpackaging cannot be empty.

-

Plasticthermoforming cannot be empty.

-

Tubes cannot be empty.

-

Luxurybags cannot be empty.

-

Plasticfoldingcartons cannot be empty.

-

Foam cannot be empty.

-

Tins cannot be empty.

-

Wood cannot be empty.

-

Flexiblepouches cannot be empty.

-

Moldedpulp cannot be empty.

-

Permanentdisplays cannot be empty.

-

Temporarydisplays cannot be empty.

-

Displays cannot be empty.

-

Single-facelam cannot be empty.

-

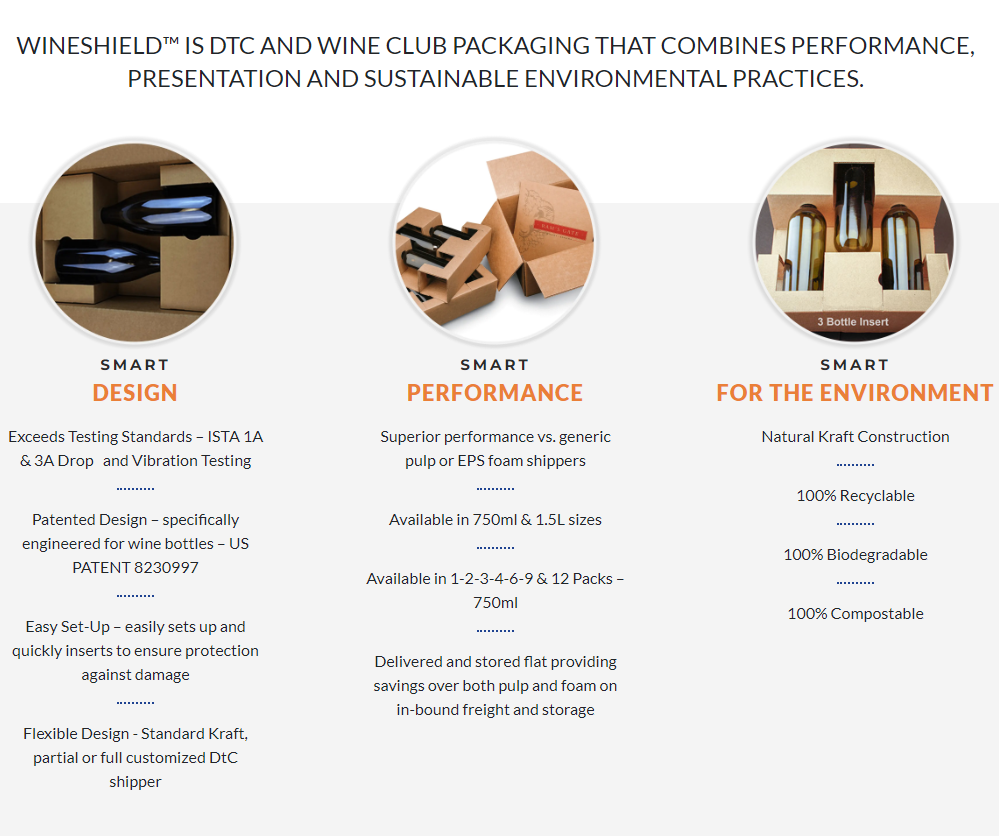

Wineshield cannot be empty.

Packaging Integrity

Your product getting into the hands of your customer undamaged is job #1. Unparalleled cross industry design experience means we’ve seen it all and know what works. Diversity of material choices ensures the appropriate substrate is used for every project.

Cost Savings

Cube utilization analysis, caliper downgrades, and board test reduction all contribute to the lowest cost effectively shipped solutions. Your packaging can be beautiful and still meet your budget, giving you the best of both worlds.

Drop Testing

We take performance uncertainty out of equation using our certified drop testing protocols. Certification means you can be refunded if your carrier damages a shipment during transit and also avoids a disappointing customer experience.

Out-Of-The-Box Experience

First impressions matter. Let us add excitement to the moment when the product first meets your customers eyes and hands. Packaging quality is often a reflection of product quality in the eyes of the consumer and will often influence buying decisions.

No Room? No Problem.

We create space for you through designing your package into a smaller form factor. This engineered approach saves valuable warehousing space, reduces overhead, and lowers shipping costs. All of this reduces material usage which helps you meet your sustainability goals.

Logistics and Efficiency

As a global manufacture, we can make sure your packaging is made as close as possible to where your product is made. This saves time to market and reduces the carbon footprint associated with each product line you launch.

.png)

.png)