Printing might not seem like a major part of your packaging business; however, it plays a crucial role. Selecting the right printing method is vital for creating high-quality packaging that enhances your brand’s image and market presence. Explore the difference between litho and digital printing to determine which option would be better for your packaging needs.

Understanding Litho Printing

Litho printing, short for lithographic printing, is a traditional technique. This process works by transferring ink from a metal plate to a rubber blanket, which the print artist then applies to the printing surface. The process begins by creating a plate that has the image you will be printing. The artist treats the plate so the image areas attract ink while the non-image areas repel it. The inked plate then encounters the rubber blanket, which transfers the ink to the substrate, completing the printing process.

Common applications of litho printing include the production of magazines, brochures, posters, stationary, and packaging. This method is especially popular in scenarios where you may need detailed, high-resolution images, making it a go-to choice for many professional graphic designers and marketers.

Understanding Digital Printing

Digital printing is a modern method that involves printing digital images from a computer directly onto a variety of media. Unlike traditional methods, digital printing does not require the creation of printing plates. Instead, digital printers use technologies such as inkjet or laser printing to reproduce images directly onto the print surface. This process allows for quick setup and easy customization for each print job.

Common applications of digital printing include producing marketing materials such as flyers, brochures, posters, business cards, direct mail pieces, packaging, and personalized stationery. Additionally, artists frequently use digital printing for small-to-medium print runs, such as on-demand book printing, labels, and packaging prototypes. This method is highly versatile, allowing for printing on various substrates, including paper, cardstock, fabrics, and even certain plastics.

Key Differences Between Litho and Digital Printing

Now that we have a better understanding of both printing methods let’s explore the key differences between them.

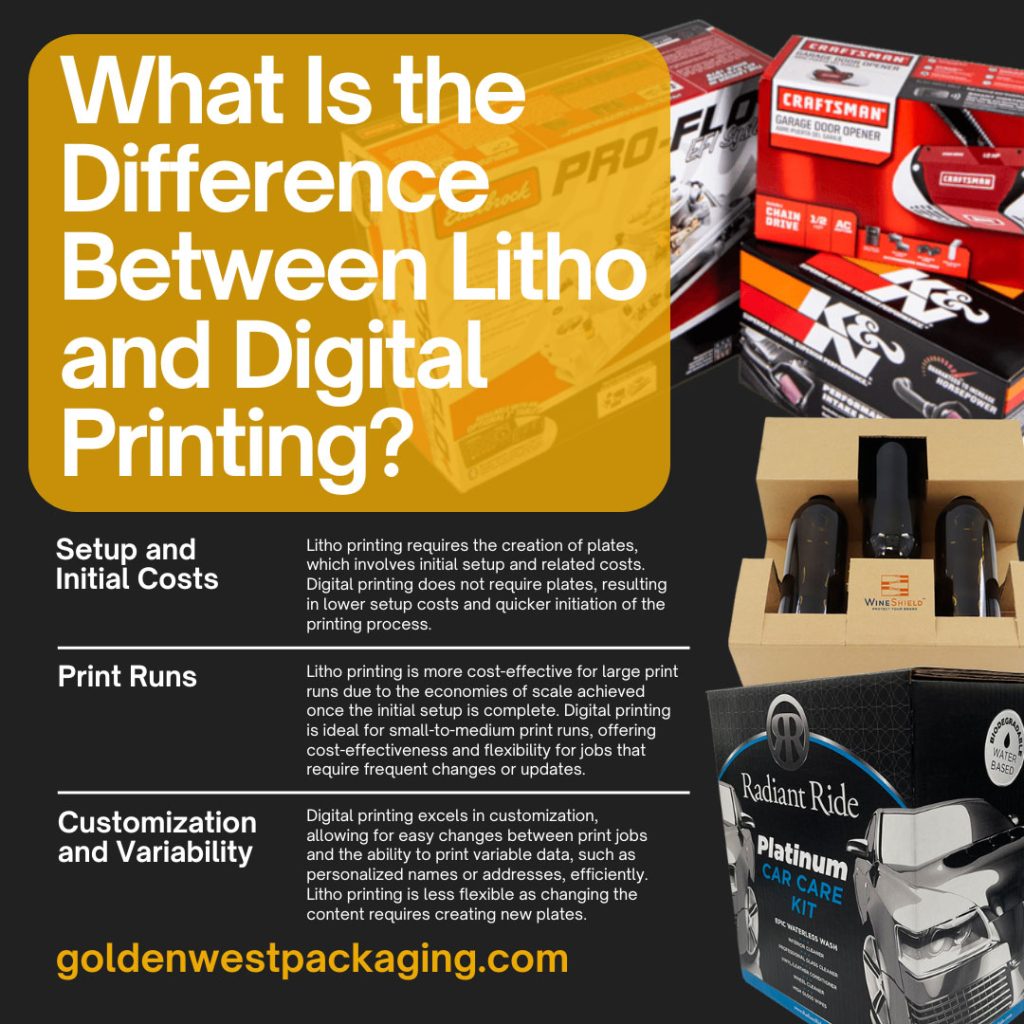

Setup and Initial Costs

Litho printing requires the creation of plates, which involves initial setup and related costs. Digital printing does not require plates, resulting in lower setup costs and quicker initiation of the printing process.

Print Runs

Litho printing is more cost-effective for large print runs due to the economies of scale achieved once the initial setup is complete. Digital printing is ideal for small-to-medium print runs, offering cost-effectiveness and flexibility for jobs that require frequent changes or updates.

Customization and Variability

Digital printing excels in customization, allowing for easy changes between print jobs and the ability to print variable data, such as personalized names or addresses, efficiently. Litho printing is less flexible as changing the content requires creating new plates.

Turnaround Time

Digital printing offers faster turnaround times since it involves a straightforward process without needing plates. This rapid setup facilitates on-demand printing with minimal delays compared to the more time-intensive litho-printing process.

Print Quality

Many laud litho printing for its high-quality, detailed, and consistent output, which is excellent for large image areas and fine text. Digital printing has made significant advancements and can produce high-quality images and text, which is particularly beneficial for projects requiring rapid delivery and varying designs.

Material Versatility

Digital printing offers greater versatility with the ability to print on many materials, including paper, cardstock, fabrics, and some plastics. Litho printing is typically best for a narrower range of substrates, mainly papers and cardboard.

Digital printing stands out for its adaptability, speed, and lower initial costs, making it especially valuable for businesses seeking flexibility and efficiency in their printing needs.

How To Choose Your Printing Option

Choosing the right printing option depends on several factors, including your project’s size, budget, and required turnaround time.

Project Size and Volume

Consider your project’s size and volume. Litho printing may be more cost-effective if you need a large print run. Digital printing is likely better for smaller print runs or personalized projects.

Budget

Evaluate your budget and determine which printing method offers the best value for your needs. While litho printing has higher initial setup costs, it becomes more cost-effective for large print runs. Digital printing is more budget-friendly as it has minimal setup costs.

Turnaround Time

Consider the required turnaround time for your project. Digital printing’s minimal setup time makes it ideal for quick print needs. Litho printing, with its longer setup process, may be better suited for projects with more extended timelines.

Print Quality

Assess the print quality required for your project. Litho printing is the way to go if you need consistent, high-quality prints with sharp images and vibrant colors. Digital printing offers the flexibility you need for detailed designs and easy customization.

Material Options

Finally, consider the materials you’ll be printing on. Litho printing has a narrow range of versatility compared to digital printing.

Golden West Packaging

Golden West Packaging utilizes a monumental digital printing press to bring unparalleled precision and quality to all your packaging needs. Our state-of-the-art equipment ensures that we can deliver vibrant, detailed, and customizable prints directly onto your packaging materials, offering flexibility and efficiency without compromising quality.

Golden West Packaging is here to partner with you every step of the way, whether you want to design printed corrugated boxes for new products or update existing designs. Our team of experts will work closely with you to understand your requirements, assisting in creating bespoke packaging solutions that stand out in the market. We ensure a seamless and efficient process tailored specifically to your needs, from concept to final product.

We invite you to reach out to Golden West Packaging to get started on your next packaging project. Let us help you elevate your brand with exceptional printed materials that leave a lasting impression. Contact us today to discuss how we can collaborate on your next project.

The difference between litho and digital printing can significantly impact your printing project’s success. Selecting the right printing method is crucial, whether you require large print runs with consistent quality or a quick, customizable solution for smaller jobs. Don’t forget Golden West Packaging if you’re seeking impeccable digital printing services.