Packaging Glossary

Adhesive: Any material which is applied to form a bond between two surfaces.

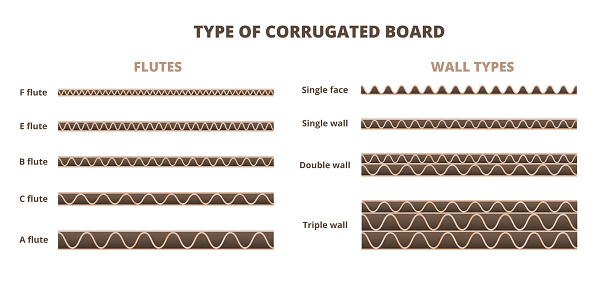

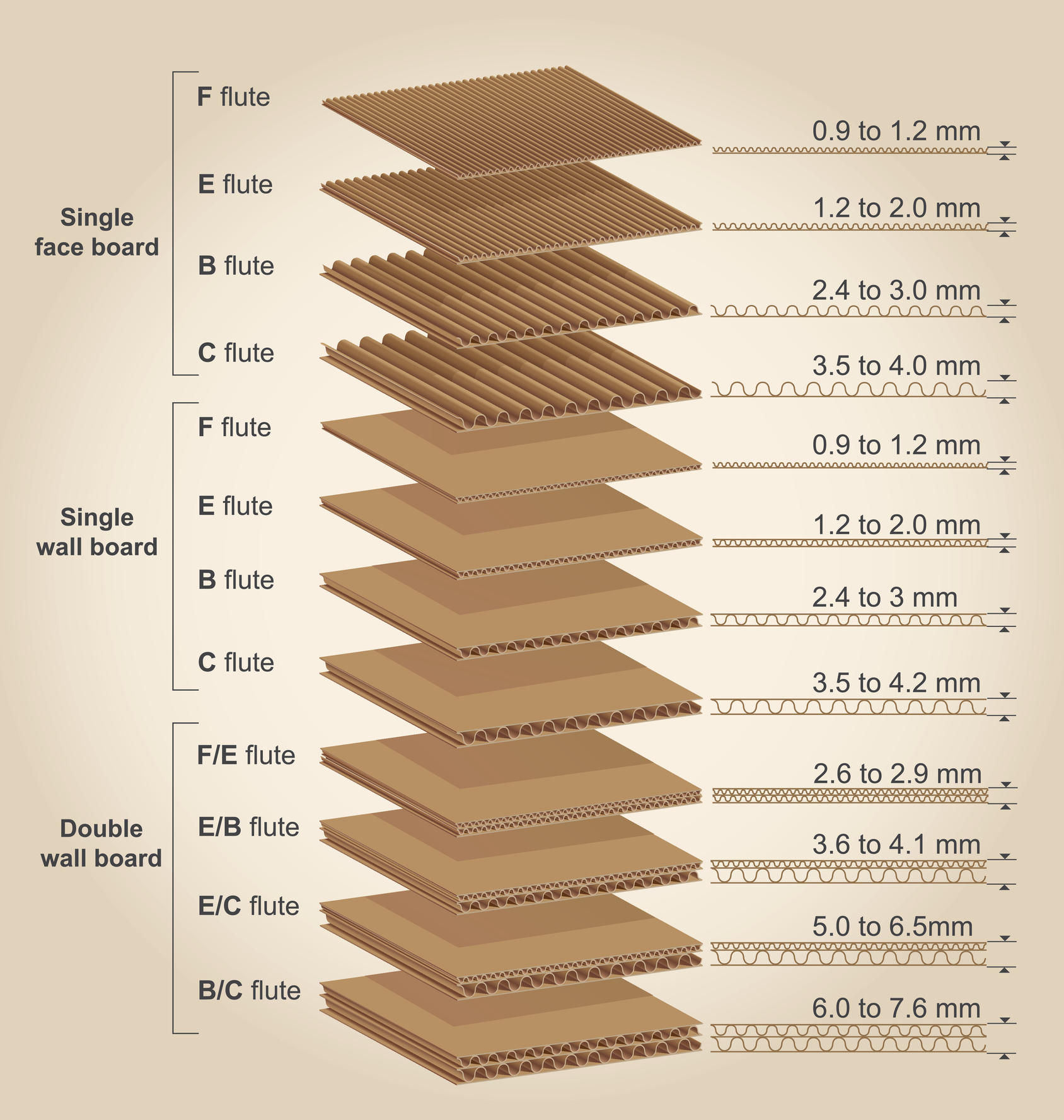

A-Flute: The thickest corrugated flute, with 33 flutes per linear foot in a ¼” in thickness.

Air Freight: Goods which are transported by air. When packaging an item the following preparation measures need to be taken into consideration; the sensitivity of the goods, the mass, dimensions and center of gravity of the packaging goods and the air humidity level inside the packaging.

Allocated Inventory: Materials that have been assigned to specific production orders in the future. These materials, therefore, cannot be used for other orders so more stock needs to be obtained.

Aluminum: Aluminum is a lightweight, highly conductive, reflective, non-toxic metal.

Anaerobic Digestion: Part of the process used to treat biodegradable waste, this process reduces the emission of landfill gas into the atmosphere.

Angel Hair: Small cut slithers of packaging material which can remain on the final product.

Artwork: The logo or graphic design that is created in order to be printed onto the packaging.

Assembly: A line to put together all the parts and components in order to make the finished product.

B-Flute: A grade of corrugated board with a total of 47 flutes per linear foot and a thickness of 1/8th of an inch.

Biodegradable: A substance that can be broken down by bacteria and other living organisms in the environment making it more ecofriendly.

Bleached Pulp: Pulp which has been whitened by an oxidizing treatment, often with a hydrogen peroxide solution, or reducing agent sulfur dioxide.

Blister Packs: Packaging which forms a mold around the merchandise, usually made from plastic and often transparent. It can be heat-sealed to make them tamper proof.

Blister Packaging: A type of packaging which secures a product between paperboard and a transparent plastic dome or bubble.

Board: A heavy thick sheet of paper with variations including cardboard, fiberboard, and containerboard.

Board Grade: A grade given to corrugated board based on three elements: the weight and type of outer liner, the type of flute, and the weight and type of inner liner.

Bonding: Joining pieces of foam or plastic together either with glue or heat to create the desired shape or thickness. Application depends on the materials to be joined and the intended use for the material.

Box Blank: A flat board that has been cut and scored and is ready to be glued or formed into a box.

Box Style: A category that can be used as a helpful descriptor regardless of box size or construction.

C-Flute: The most commonly used corrugated material grade. C-flute offers good crush resistance, high printing properties, and a good stacking strength. C-flute has 39 flutes per linear foot and a thickness of 3/16th of an inch.

CAD: CAD (or computer-aided design) refers to the use of computer software to create engineering drawings for 2D and 3D designs.

CAM: CAM (or computer-aided manufacturing) is a computer application technology used in tandem with CAD to link and control production equipment. The technology will feed data into the manufacturing equipment in order to achieve its desired effect.

Capacity: The volume of space within a container to hold the given amount of product.

Caps: End caps used to close packages. For example, a plastic end cap will be used to seal the contents inside a corrugated mailing tube. Can also refer to foam or cushioning material that is placed over the ends of a product for protection during transit.

Carton: A box or container made of paperboard or corrugated fiberboard.

Carton Board: Carton Board is stiffer and thicker than boxboard. It has a medium to high compression and moisture resistance. Unlike cardboard, it is solid, and not fluted.

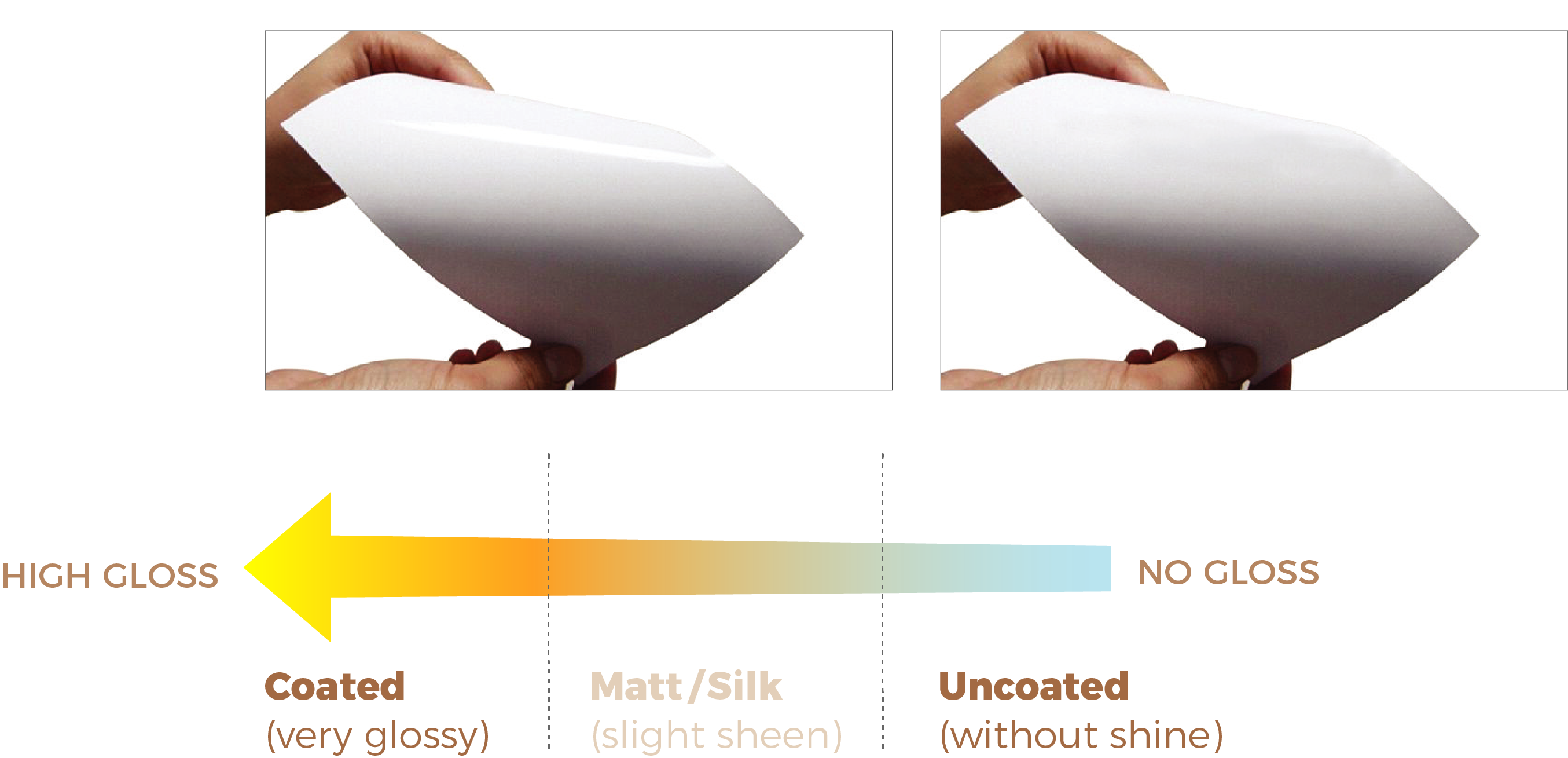

Coatings: Special coatings used on a packaging substrate for a variety of reasons including waterproofing, anti-abrasion, and anti-corrosion.

Collapsible: A packaging structure that can be folded down flat (flat-packs) making bulk transportation easier.

Color Mockup: A full-color rendering or sample of a given product’s packaging, created for the purposes of inspection, and perfecting of the final packaging design before production.

Contract Packaging: An agreement to provide a company with an end to end packing service—manufacturing the packaging containers, then providing the human resource and infrastructure to assemble, kit, and load finished goods for distribution.

Co-Packer: A company specifically hired to manufacture and package products for a business partner.

Corrugated Fiberboard:An industry term for what is commonly referred to as cardboard, comprised of flat and ridged layers of paper material.

Countertop Display: A compact type of retail packaging display similar to a floor stand but small enough to fit on a shelf or countertop.

Cushioning: Packaging cushioning is used to protect fragile and sensitive items during transit.

Custom Packaging: Non-stock packaging designed for specific needs or to feature business branding.

Deboss: To stamp a design onto the surface of an object so that it is indented.

Demo Case: Also called a sample case, demo cases are used for the presentation of goods during sales meetings or pitches.

Density: The weight of a gas, liquid or solid substance which is measured in grams by cubic centimeter.

Die: A type of tooling that allows for customized branding of packaging products.

Die Cutting: A procedure in which a die will be used to stamp the required scores and cuts of a specific packaging design onto the material (e.g., corrugated board).

Dieline: A template used in graphic design indicating cuts, scores, etc., which assists in the creation of the proper layout for a printed item that will be die cut as part of the finishing process.

Digital Printer:An industrial scale printer with the ability to print in multiple colors simultaneously without the need for plates. Ideal for smaller runs on custom packaging.

Dimensions: The measurable extent of the packaging usually length, depth, and height.

Direct Print: A type of printing done directly on the surface of the packaging substrate, rather than a label or laminate.

Dividers: A device which separates sections within a container. Dividers can be plain, scored, and/or interlocking. They can be used to provide cushioning as well as separation.

Double Wall Board: A combination of two layers of corrugated material (potentially different flute sizes) to provide a material with extra strength.

Drawing: A technical drawing of the packaging design, usually attached to a CAD specification sheet.

Drop Test: A test used to determine the durability of the subjected packaging. The packaging is dropped from a specified height to verify the survival of the product inside without incurring damage.

E-commerce: Commercial retail transaction conducted online.

E-commerce Packaging: Packaging designed to keep products safe in transit from the online retailer warehouse to the purchaser.

E- Flute: A corrugated flute grade that generally has a greater crush resistance than the other flutes and a flat surface, which makes for high quality printing. E-Flute has 90 flutes per foot and a thickness of 1/16th of an inch.

Embossing: Raised lettering or design on a form of packaging, made from pressure dies, printing press, or rollers.

End Caps: 1. Foam cushioning which provides protection for a product placed within corrugated packaging. 2. A gondola placed at the end of an aisle at retail.

Estimate: A quote based on the cost of materials, manufacturing method, and required quantity of the product.

Fiber: Material that comprises different types of packaging materials, such as molded pulp.

Flatbed Die Cutting: A process used for cutting, creasing, and embossing sheet materials. The die is pressed onto material which is itself on a flat surface (the bed).

Flat Pack: Packaging which is flat when shipped to minimize transit costs.

Flight Case: A custom built case (can be tailored in size) historically used in the broadcasting and performance industries.

Flood Coat: The coating of an entire surface with a color or dye.

Flute: The ridged layer of paper in corrugated board that is sandwiched between two liners, creating the strength and rigidity of the board. Please see appendix 1 for further details and the most common flutes.

Flute Direction: Flute direction is the direction of the ridges of the fluted material on the board. It is either vertical or horizontal. Flute direction is important as it impacts the strength and structural integrity of the corrugated board.

Foam: A substance which is formed by the process of trapping pockets of gas in a solid material. Different types include XPS foam, polystyrene, and polyurethane.

Foam Lining: An inside foam liner (see foam) of a case which is used to protect the objects inside the case.

Folding Carton: Carton usually made of paperboard that is folded, printed, laminated, cut, and glued and then transported ready to be filled and closed by the retailer. A common example is cereal boxes.

Fulfillment Center: A facility where products are picked, packed, and shipped after customer purchase.

Gloss: A coating which provides a higher reflection of light, resulting in an appearance of shine. It provides good color definition and contrast.

Hanging Tabs: Tabs which hang merchandise in its packaging, often self-adhesive (clear).

Heat-Seal: A method of sealing two or more surfaces together. Heat can join either two similar materials together or can even join materials which are dissimilar with a thermoplastic layer. The method is controlled under temperature and pressure conditions.

Hot-Melt Adhesive: Also known as hot glue or HMA, it is a solid at room temperature but once heated is a liquefied adhesive.

ISO 9001 Certified: ISO 9001 certification means a business has met the provisions held in ISO 9001, a quality management system (QMS) written by members of a worldwide delegation known as the ISO (International Standards Organization). The focus of ISO 9001 is on meeting customer expectations.

Kraft Board: Brown board that has not been bleached white or dyed another color.

Labels: An informative small document attached to an object, often containing bar codes, shipping, and production information on packaging.

Laminate: A film that can be applied to packaging to enhance its properties.

Laser Etching: An engraving process where lasers are used to engrave a design, pattern or text into a material i.e. foam.

Lead Time: The amount of time necessary for certain stages within a supply chain to be fulfilled, such as packaging production or product delivery.

Liner: One of the paper materials that makes up one part of the component in corrugated board. There is an inner and outer liner; the outer is usually of higher quality due to being used for print finish.

Lithography: The printing of flat surfaces by the use of plates.

Litho Laminated Print: A high quality printed, and coated press sheet affixed to corrugated board prior to the die cut process.

Manufacture: The making of goods on a large scale by machinery and/or manual labor.

Master Packs: A type of packaging designed to ship retail products to stores in shelf-ready packaging, typically made of corrugated fiberboard.

Materials Handling: A system designed for the storage and retrieval of materials in manufacturing and distribution (e.g., bins, totes etc.)

Matte Finish: Can also be referred to as a flat finish, a matte finish is a coating where the surface displays no gloss or shine.

MOQ: "Minimum Order Quantity" or the minimum amount a supplier may require in order to manufacture a product.

Offset Litho: Mass production printing using the offset printing technique.

Offset Printing: A printing process where ink is transferred from a printing plate to a rubber blanket or roller, and then subsequently to the sheet. A practical method for multiple color labeling.

Pallets: A flat transport structure which supports goods stably, often in the form of wood. Allows for easy lifting and movement by forklifts.

Pallet Boxes: Large industrial boxes fixed to or on top of pallets, which can be used to ship products in bulk.

Pantone: A widely used proprietary color system for matching color and printing inks.

Partitions: A sectioning device within a container. Partitions can be corrugated, scored or interlocking. They provide cushioning as well as separation.

Performance: A reflection of productivity, output, strength, and other measurable metric.

Pillow Pack: A pillow pack box is a type of packaging which pops into shape and resembles a miniature cardboard pillow. It has interlocking tabs and is ideal for smaller products.

PDQ Display: "Pretty Darn Quick" displays designed for store employees to unpack and shelf merchandise quickly and efficiently.

Platen/Plate: A press with which one flat surface is pressed against another. Short-run die cutting presses are often platen presses.

Plywood: A thin but strong wooden board consisting of two layers or more glued and pressed together with the grain direction alternating.

PMS: An acronym for Pantone Matching System, a color matching system used in the print industry. See also Pantone.

Polyethylene: Also abbreviated to PE, polyethylene is the most commonly used plastic. It is translucent, tough, and a waxy solid which is unaffected by water and by a large range of chemicals. It has three classifications: low density, medium density, and high density.

Polyethylene Foam: Closed cell foam which is strong and resilient chemically.

Polymer: Large molecules which are made when smaller molecules join together i.e., polyethylene. These can be natural or synthetic.

POP Display: "Point of Purchase" displays include stylish signage and are designed to highlight and promote a product at retail.

POS: "Point of Sale" displays usually contain promotions and can often be found next to or near the register.

Pulp: Material prepared by chemically or mechanically separating cellulose fibers from wastepaper, wood, and fiber crops.

PVA Adhesive: PVA (or polyvinyl acetate) is a rubbery synthetic polymer commonly used in glue. It is also a type of thermoplastic.

Quote: A packaging quote will initially be provided by an estimator or salesperson and will usually provide the following information: quantity, unit price and total price, the customer’s details, and item descriptions.

Recyclable: Packaging materials that can be processed for re-use rather than waste.

Run: How many items produced in one manufacturing “session”.

Sampling: Creation of a prototype to allow customer approval before mass production.

Sample Case: Used by salespeople to showcase their products to potential customers.

Sheet: Term for referring to raw material (e.g. corrugated sheet, Correx® sheet).

Sheet Feeders: A plant that operates a corrugator to run corrugated sheets, especially for box plants to convert into boxes.

Sheet Plant: An independent company who buy their materials from sheet feeders to then convert the materials into packaging. A sheet plant will not have a corrugator.

Silk-Screening: A printing technique whereby a mesh is used to transfer ink onto the container to be printed. This method can be applied to closures, liners, and most containers regardless of shape or size.

Single Pass Printing: A single pass printer will allow quick printing of four color and monochrome data in one pass.

Single Source: A single source packaging supplier will supply all of a customer’s lines. Allows for cost savings and makes management of a customer’s packaging inventory simpler.

Single Wall: Also known as double faced, single wall consists of a single layer of corrugated paper bonded with material (usually paperboard) on both sides.

SKU: "Stock Keeping Unit," generally refers to different packaging versions of related products.

Sleeve: A paperboard sleeve which can be customized in shape and style to be slid over the top of another form of packaging usually for informative and decorative reasons.

Small Run: A limited order of packaging, the minimum amount of which varies from manufacturer to manufacturer.

Sourcing: All of the functions involved in the growth, harvest or extraction and processing of raw materials, including the collection and processing of recycled and reused materials.

Spec Number: A five digit specification number given to a design which could then be followed by the oblique if a design has been upgraded.

Supply Chain: Defined as a network created amongst different companies in the producing and handling of a specific product.

Sustainability: The development and use of packaging materials that increases the life cycle of material reducing the environmental impact.

Tear Strip: Plastic film or cord applied mechanically to the inside of a package, which means a package can be opened quickly.

Thermoforming: A manufacturing process which is vacuumed or pressured. Thermoformed packaging is available for food and product displays, blister packs, clamshells and tri-folds.

Tooling: Physical material that helps to make custom packaging, such as a die or mold.

Transit: The action of passing across/transporting goods from one place to another i.e., shipping, couriers, etc.

Unit Cost: The total expense incurred by a company to produce, store and sell one unit of a product. Unit costs include fixed costs, overhead costs, material costs and labor costs.

VMI: "Vendor Managed Inventory" is a process in which a packaging company will use an advanced stock management system to keep a business’s packaging levels within the agreed minimum and maximum levels.

Warehousing: The storage of parts/components.

Wastage: Components or packages produced that do not meet a required quality standard.

Web: An unbroken sheet of paper or paperboard.

Start your packaging journey with Golden West Packaging

Get in touch with our product specialist now

Get Started